Our Company

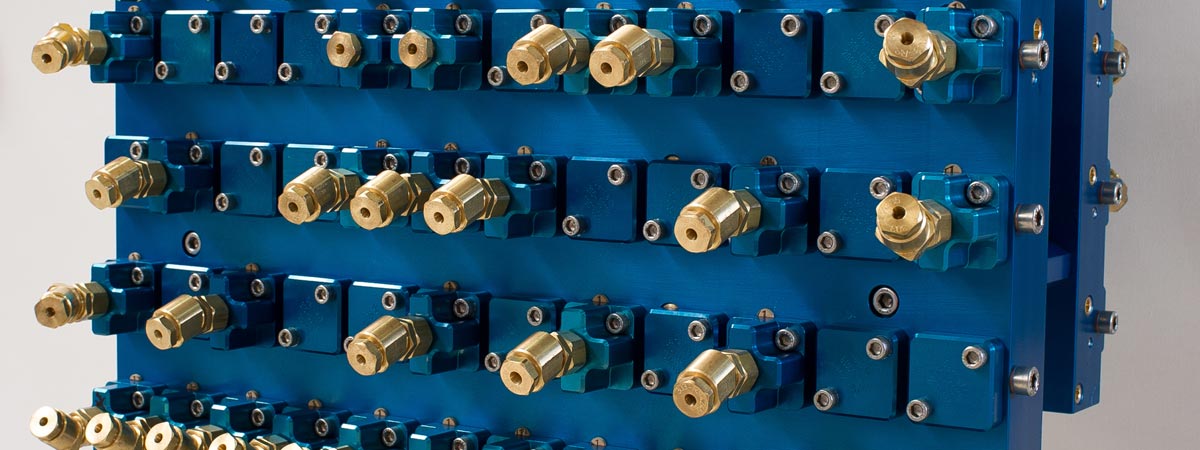

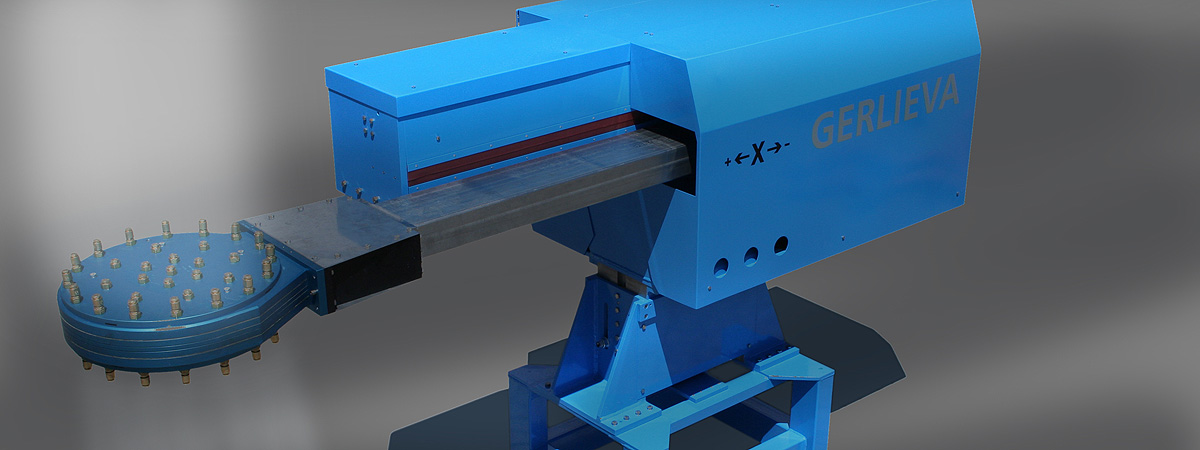

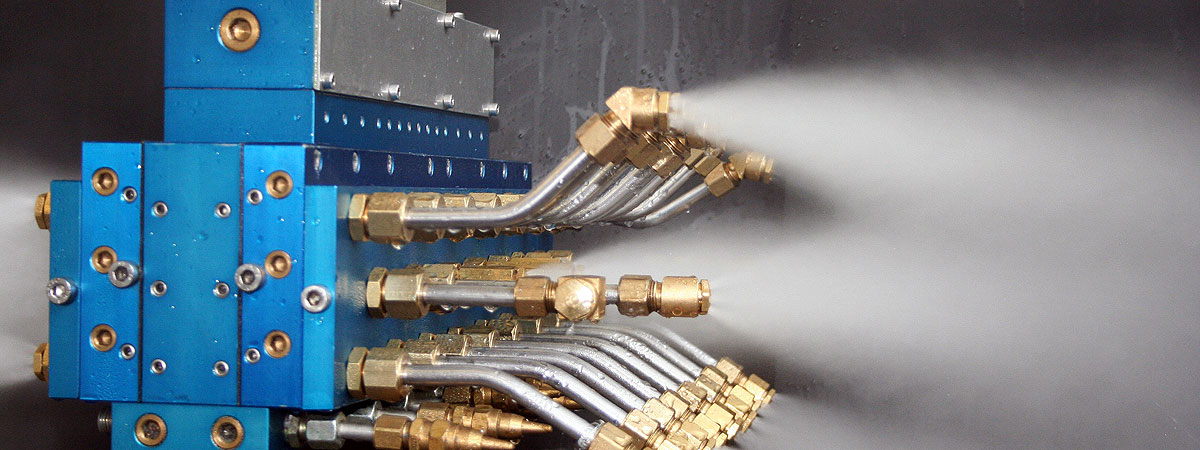

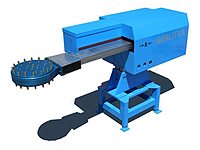

As a leading manufacturer of high-performance die spray systems for die casting and forging, GERLIEVA has been working continuously in the field of spraying technology for over 45 years, and with its knowledge and ability sets national and international standards. Numerous customers put their trust in our long experience and competence. In a production area of 3,500 m², at state-of-the-art workplaces we design, develop and manufacture complete and individual solutions.

With 90% of our production manufactured in-house, we comply with the strictest requirements and provide our customers with products that never fail to fascinate.

News / Current

-

News March 2024

Press release from Foundry-Planet on the subject of customized sprayheads!

-

News January_1 2024

EUROGUSS 2024 is already over! We would like to warmly thank you for your visit to our trade fair stand.

-

News January 2024

Press release from Foundry-Planet on the subject of dosing systems!

Die Casting

- Non ferrous warm chamber and cold chamber die casting

- Die casting machines 40 - 5000 tons of closing force

- Special applications (thixoforming, squeeze and many more)

- Spray and blow-out nozzles

Forging

- Hot forming, warm forming and cold forming in steel forging

- Aluminium, brass and copper forging

- Special applications (sintering, cold calibration and many more)

- Spray and blow-out nozzles

Peripheral devices

- Spray medium containers

- Dosing systems

- Barrel stations

- Media flow monitoring

- Test and rinsing equipments

- ff fff ff ff ff ffff ff ff ffff fff ff ff fff ff ff ff ffff ff ff fff

Our services

- Commissioning of our equipment on site

Ecological Responsibility

Because we are very conscious of our ecological responsibility, the solar power installations on each of our two modern factory buildings with a combined power output of 125 kWp cover the entire annual electric power requirement of our company. They save approximately 90 tonnes of the greenhouse gas CO2 every year. This is our major contribution to climate protection.

Support

Do you have questions or problems we can solve for you? We are here to help - call: +49 (0)7634 56912-0

Address

GERLIEVA Sprühtechnik GmbH

Tiergartenstraße 8

79423 Heitersheim

GERMANY

Telephone: +49 (0)7634 56912-0

Telefax: +49 (0)7634 6620

Email: info@gerlieva.com